The ventilators, which are required by patients in intensive care units (ICU) who are seriously ill with respiratory diseases like COVID-19, flu, and tuberculosis, are both simpler and cheaper to make than currently available ventilators.

Now, the creators of the designs hope that their promising technology, initially developed for emergency short-term ventilators in response to the coronavirus pandemic, will help to address the shortage of mechanical ventilators in developing countries in the long term.

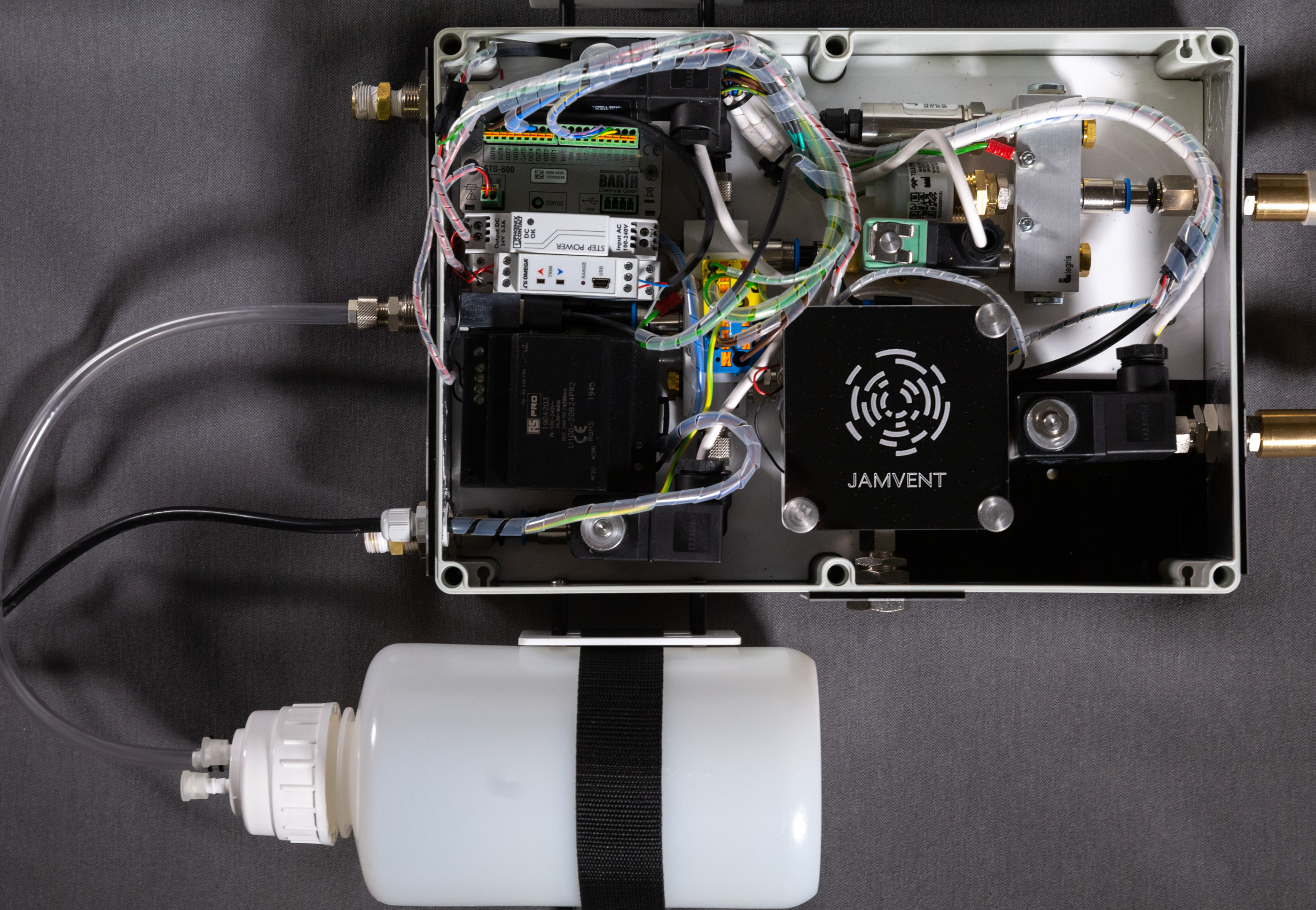

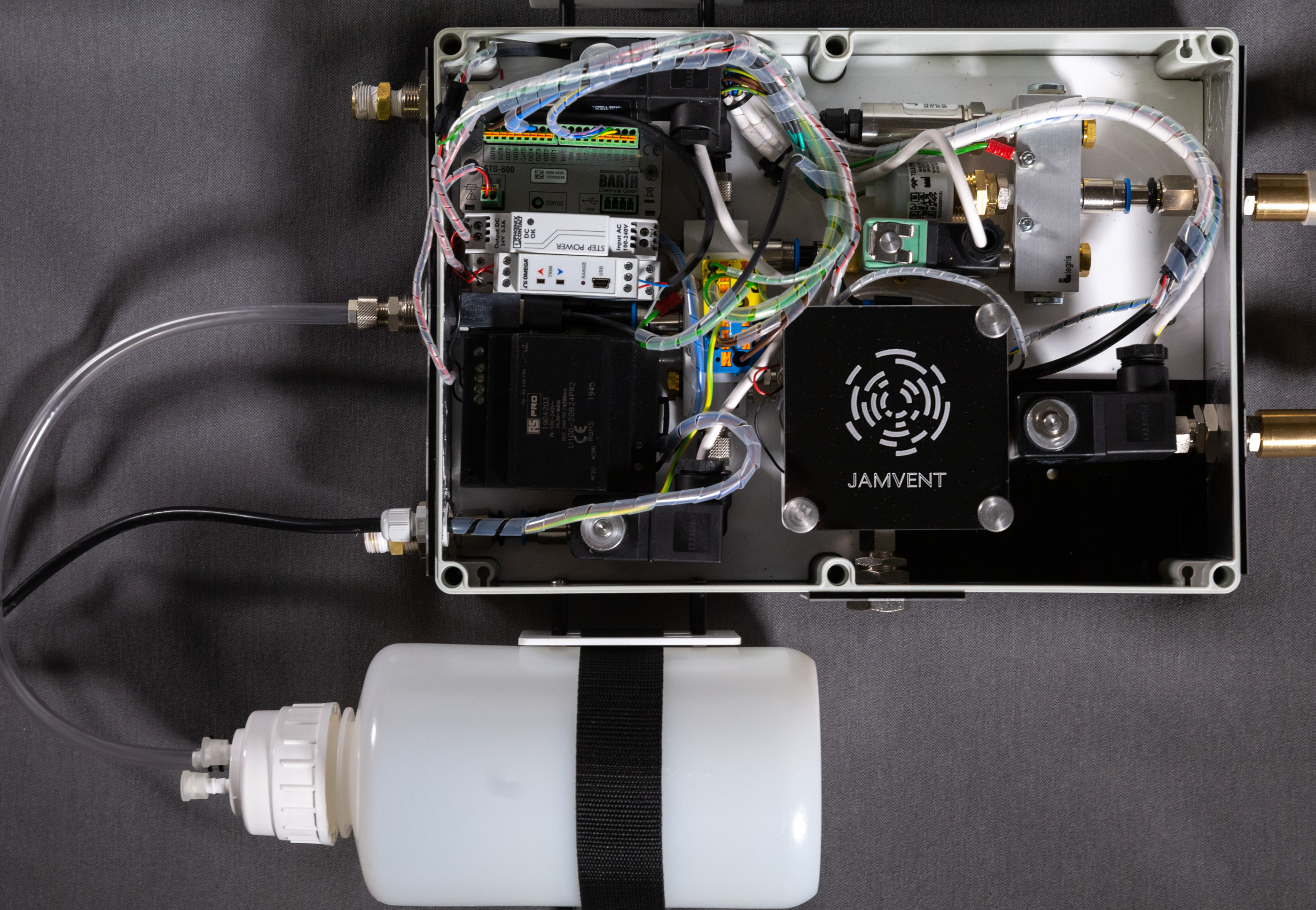

In a new paper published in Frontiers in Medical Technology, the researchers behind the ‘RELAVENT’ ventilator (previously known as JAMVENT), have demonstrated that the design achieves all of the performance requirements set out in ISO 80601, the international standard for critical care ventilators. The team also showed that the system performs equally well with a home-use oxygen concentrator as with pressurised gas supplies like those found in hospitals.

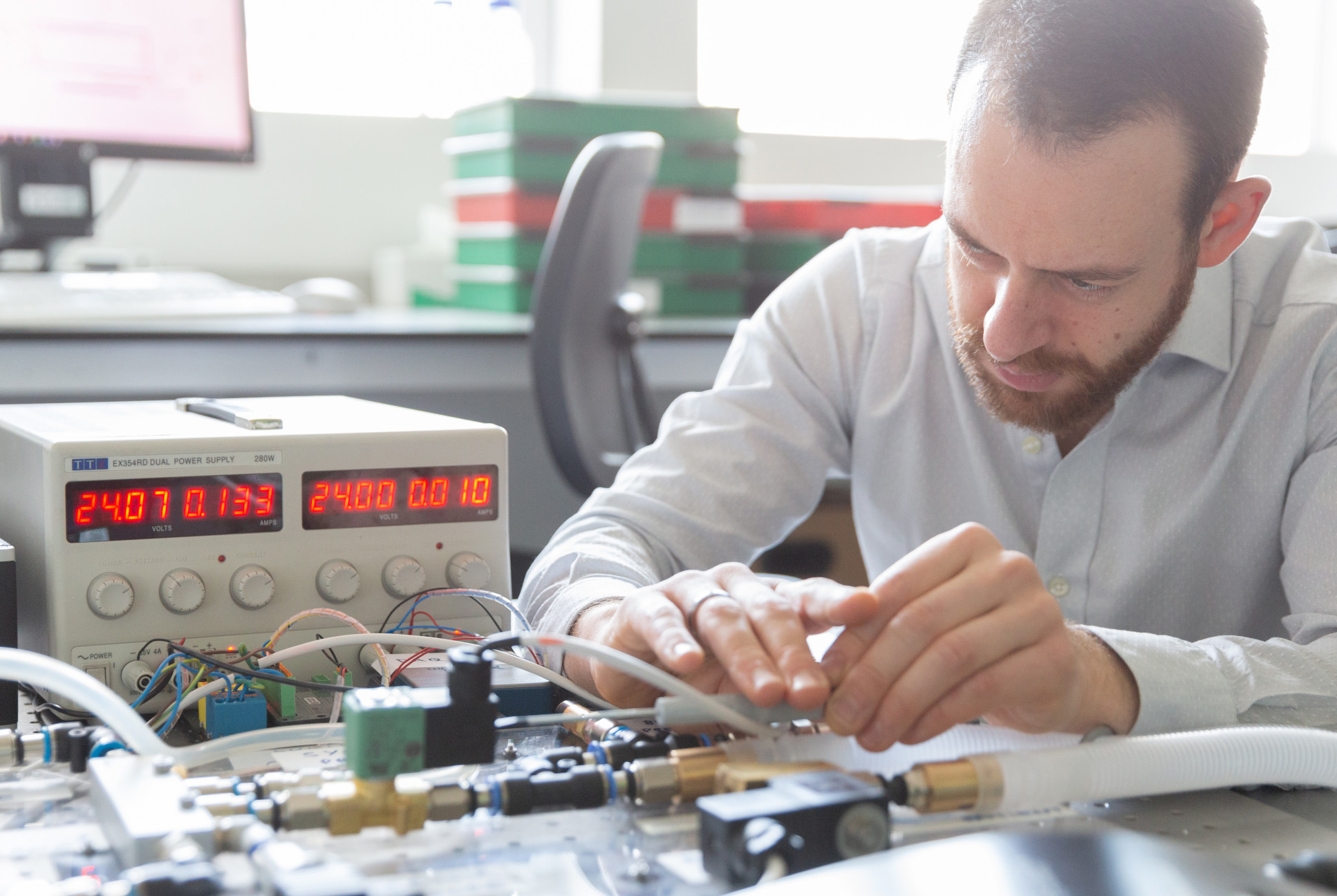

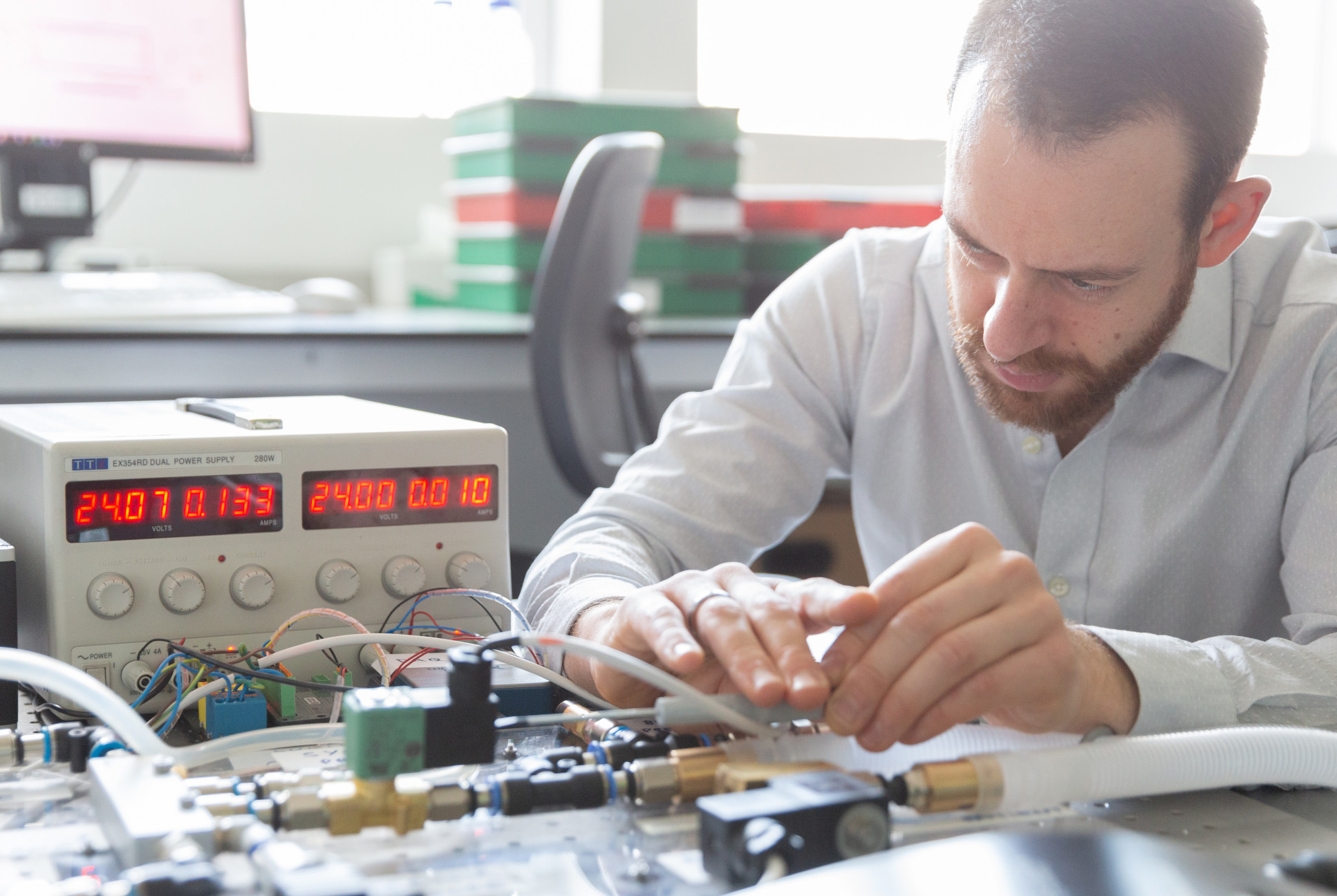

The paper also sets out the designs of the prototype and details the rigorous testing required for regulatory approval. They hope that following funding and approval as a medical device, the ventilators can be used in low-and-middle income countries (LMICs) and newly emerging economies (NEEs), which suffer from an historical long-term shortage of ventilators.

Lead researcher Dr. Joseph van Batenburg-Sherwood, of Imperial College London’s Department of Bioengineering, said “ICU ventilators made by big manufacturers have always been too expensive and complex for developing countries to buy and maintain, so many of the less affluent parts of the world simply have minimal access to ventilators. In addition, most of the new ventilator designs created for COVID-19 were based on emergency short-term manufacturing and are not appropriate for long-term intensive care support, which is desperately needed in LMICs and NEEs.”

The next step towards approval as a medical device will be development from the advanced prototype stage to a mass-manufacturable medical device, which must be carried out under special regulatory conditions. To do this, they have launched a start-up, known as Phaedrus World Medical Limited alongside two experienced med-tech entrepreneurs. They are currently seeking investment to turn their designs into useable ventilators.

Liz Hughes, CEO of Phaedrus World Medical Limited, said “RELAVENT delivers simple yet high performance mechanical ventilation. Its versatility enables access to respiratory support across many different treatment areas, and has the potential to save many lives. This has only been made possible by the efforts of the amazing Imperial College engineering team alongside clinical input from our medical advisor who has firsthand experience in our target markets.”

The beauty of simplicity

Co-author Dr. Jakob Mathiszig-Lee, of Imperial’s Department of Surgery & Cancer, said “In the UK we suffered a shortage of mechanical ventilators to treat our sickest COVID-19 patients, but such a shortage of reliable mechanical ventilation is the norm in much of the world. In LMICs and NEEs other respiratory diseases such as tuberculosis, pneumonia and influenza result in more deaths every year than COVID-19.”

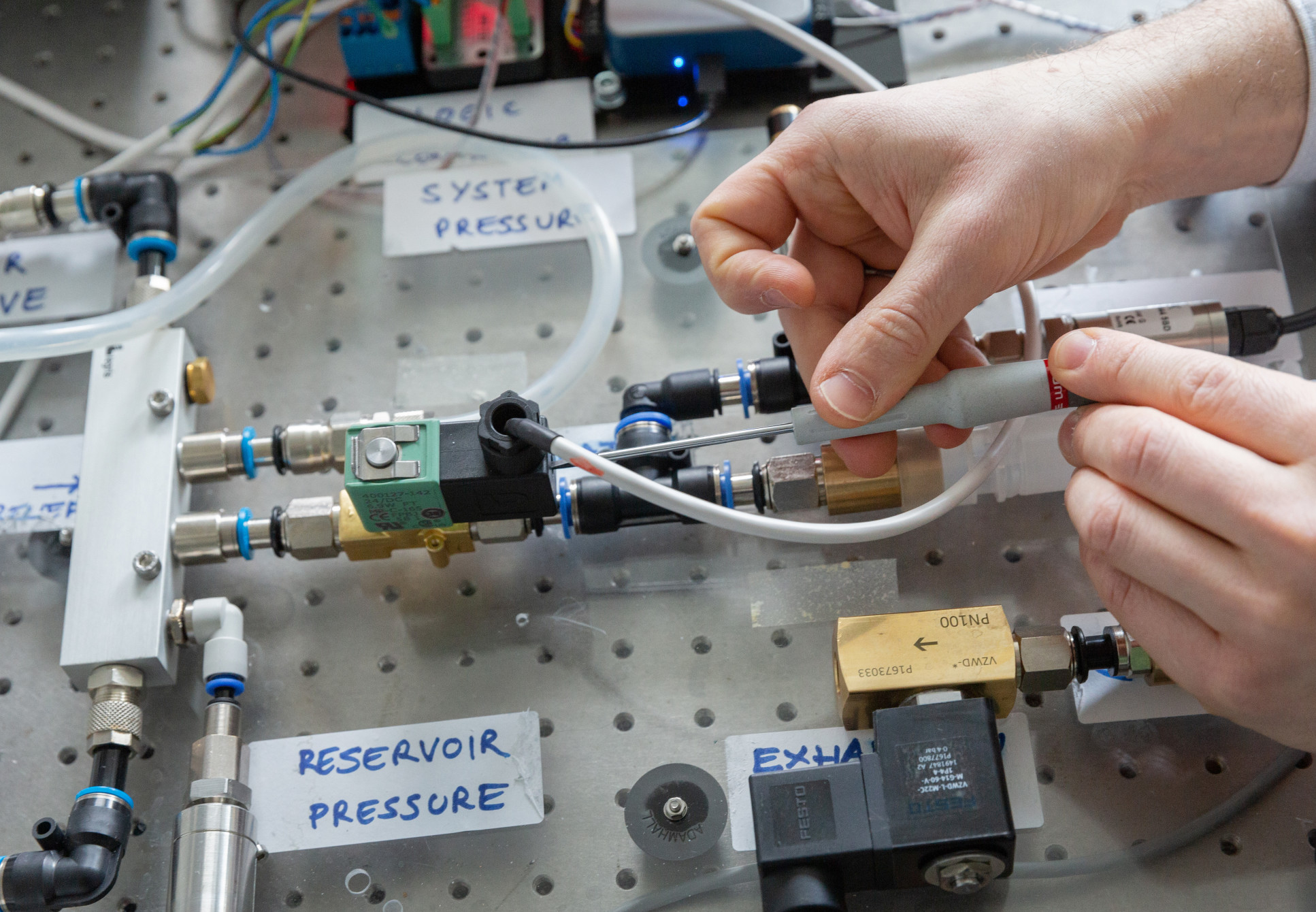

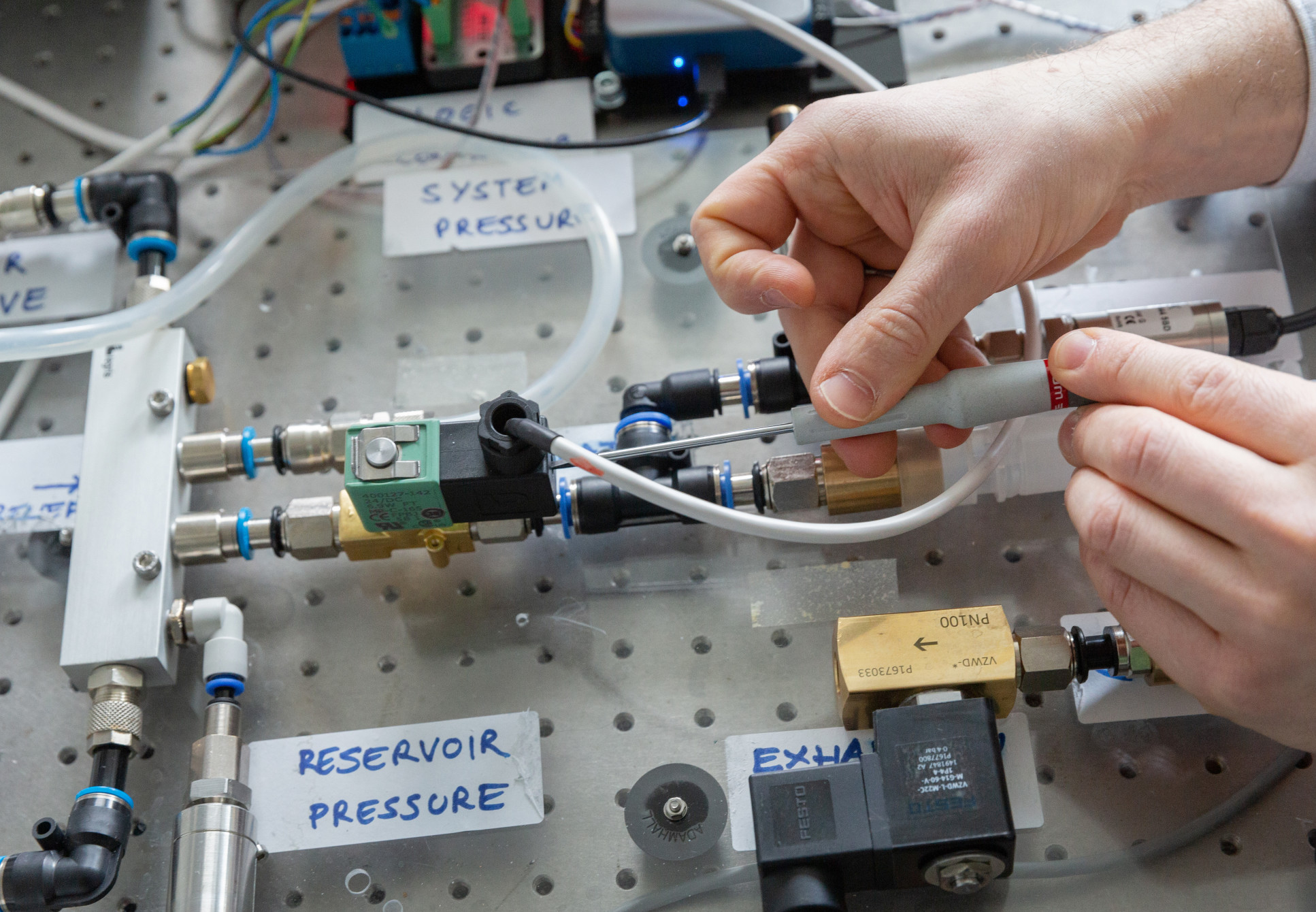

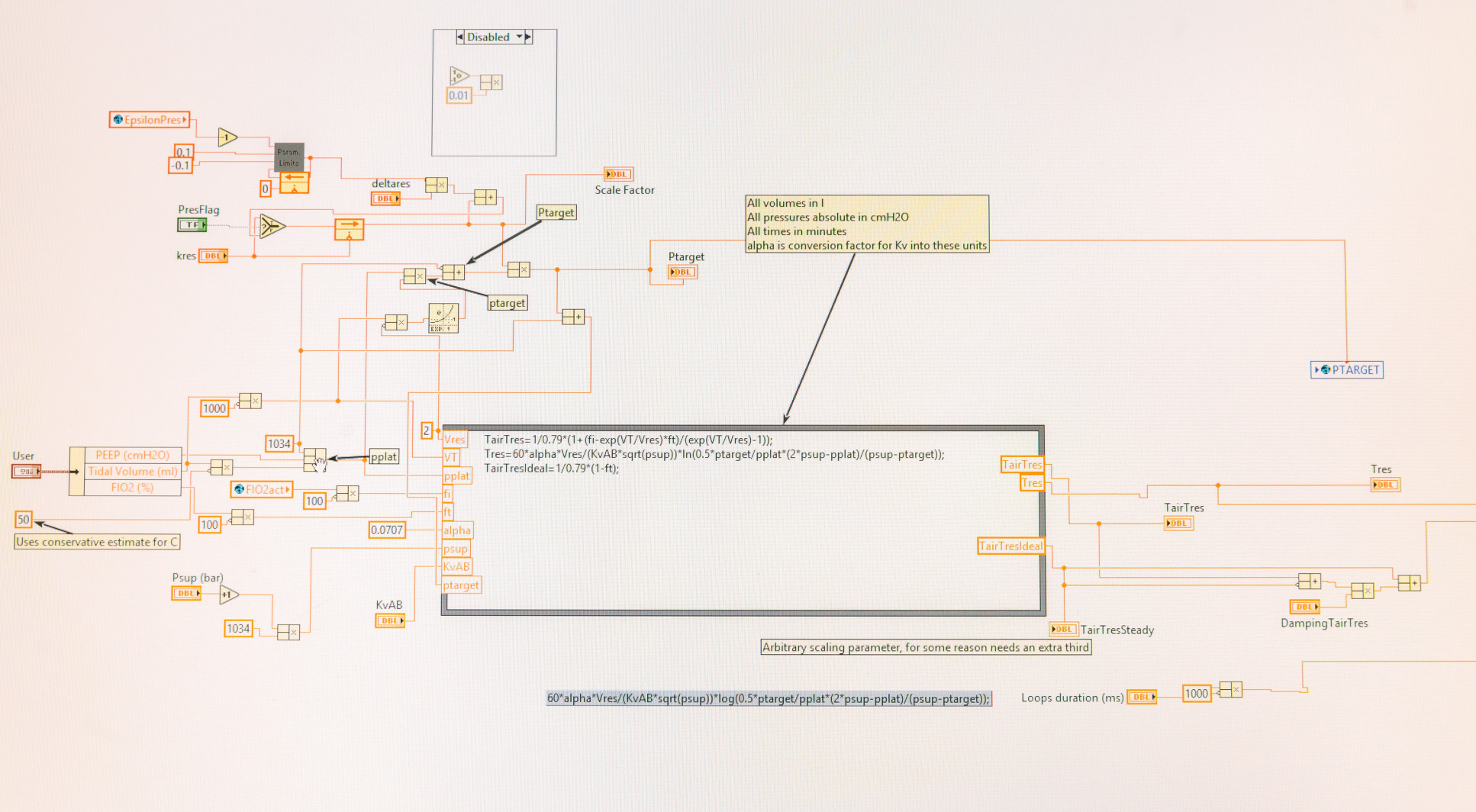

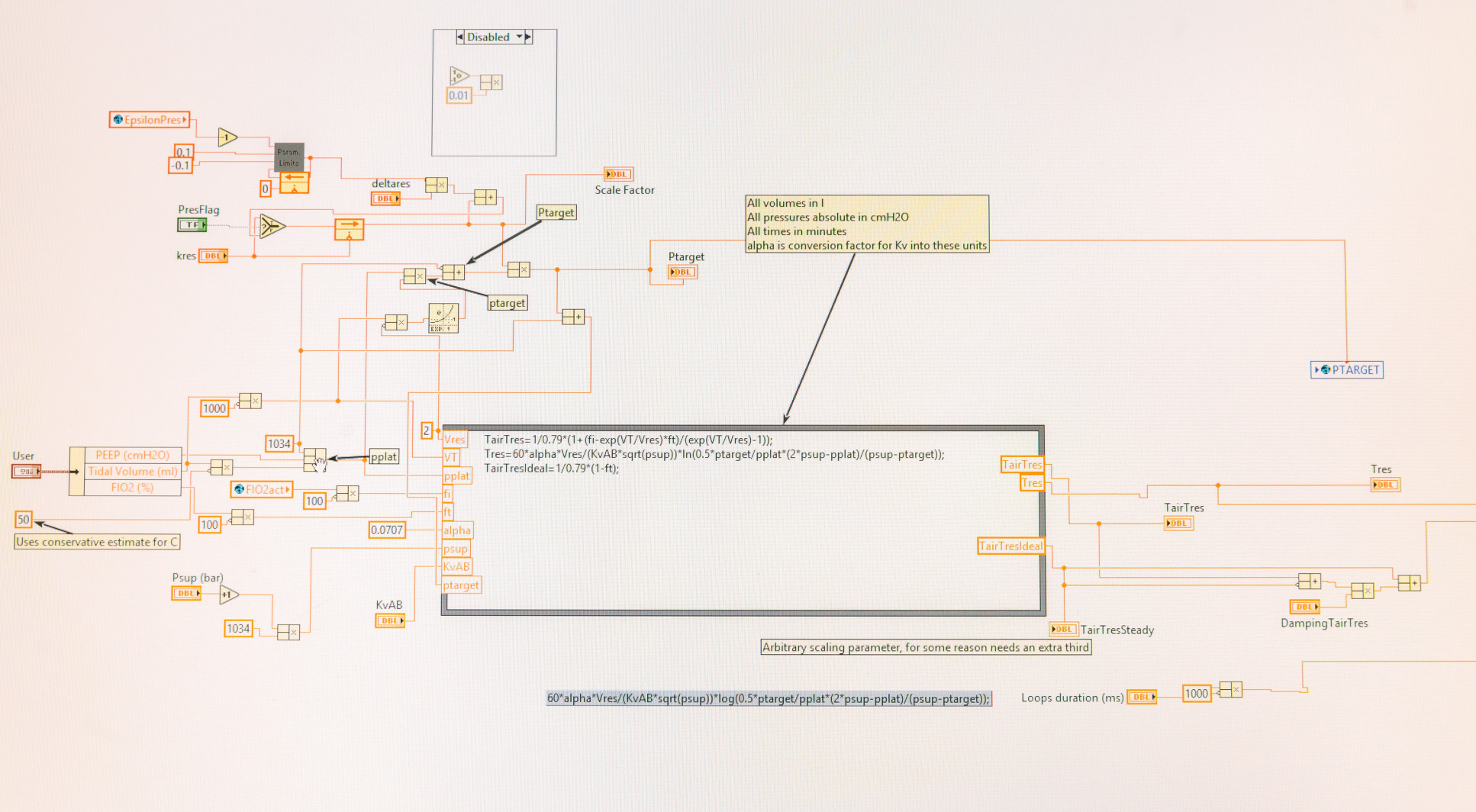

Dr. van Batenburg-Sherwood added “Our ventilators are inspired by the beauty of simplicity. Rather than using the complex control valves used in most ventilators, we conceived a way to use simple on-off valves to provide the high-level performance required of ICU ventilators. This way, we have made the technology much cheaper and less expensive to make and maintain.”

Co-author Professor James Moore, Director of Translation for Imperial’s Department of Bioengineering, said “We are keen to bring our ventilator to as many hospitals as possible to combat serious respiratory diseases worldwide. We have the right technology to help address this unmet medical need and hope to attract investment to help take it further.”